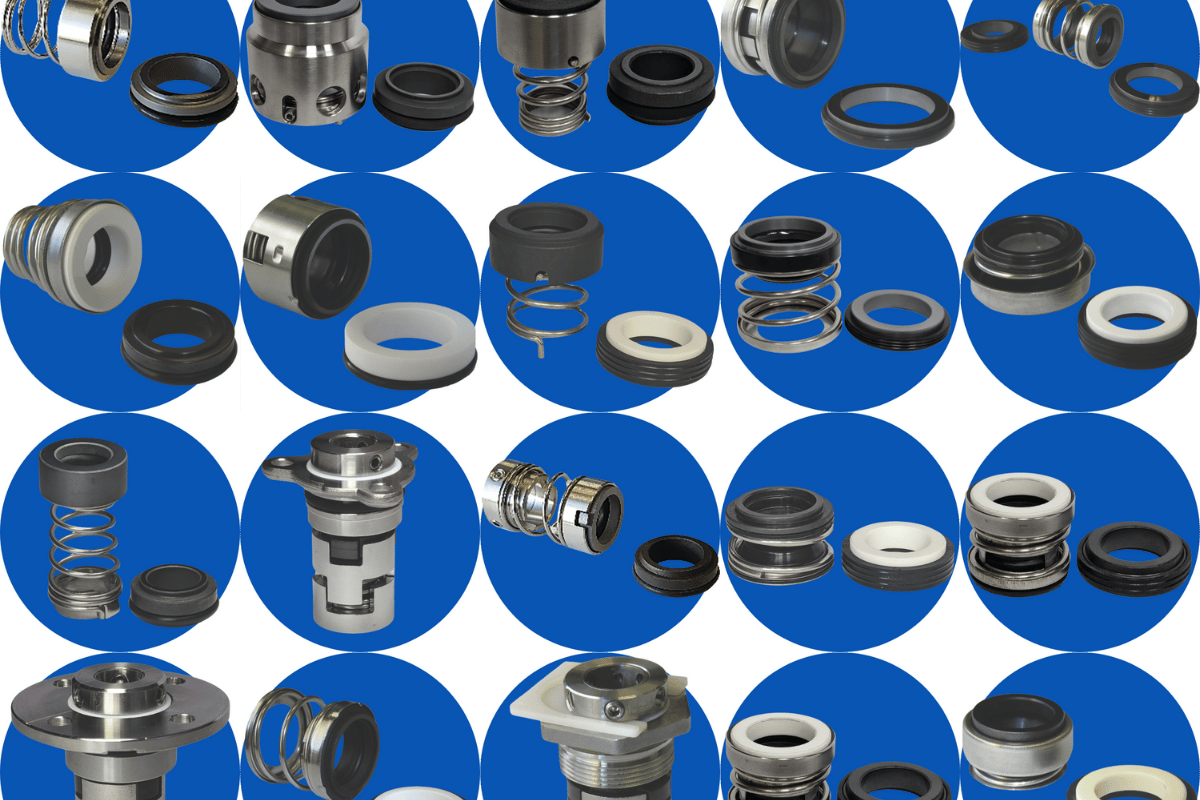

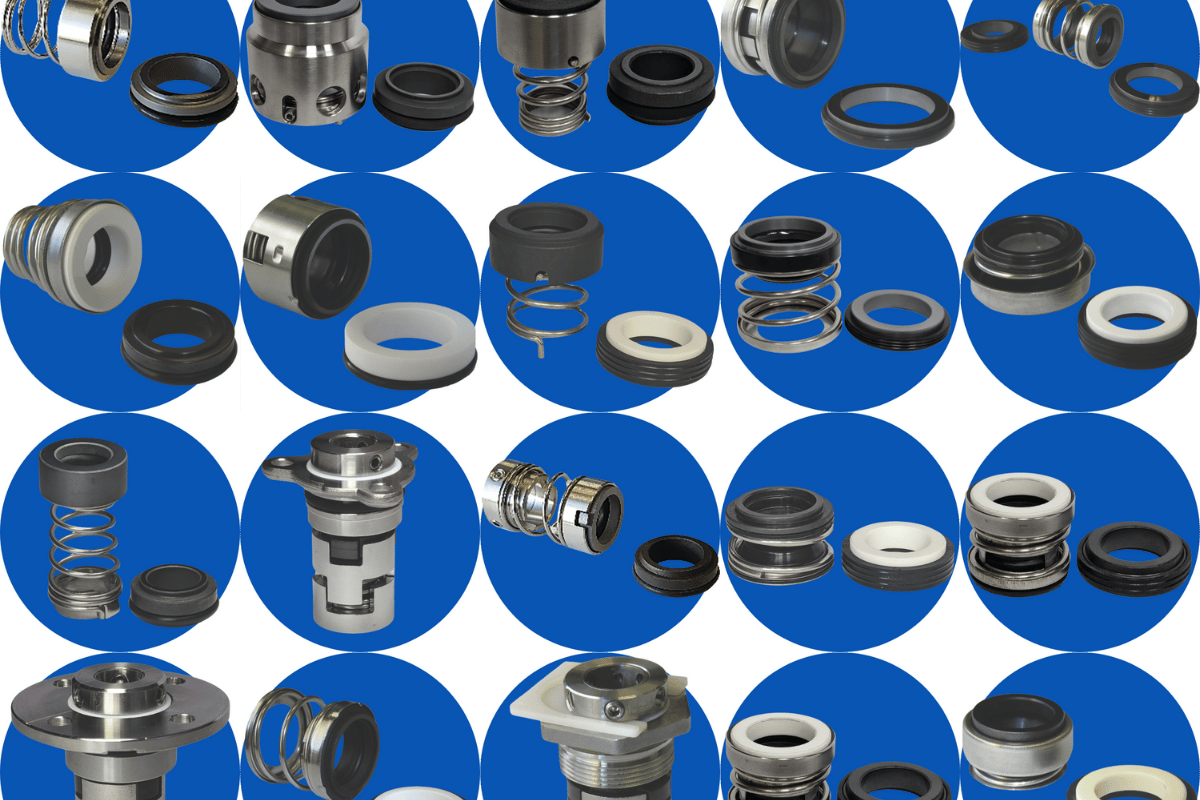

Types of Mechanical Seals

Mechanical seals are used to prevent fluid leakage along the rotating shaft in a pump (or other rotating equipment like mixers and compressors). It forms a seal between the rotating shaft and the stationary pump housing (or casing), preventing the process fluid from leaking into the environment. There are many different types of mechanical seals for the multitude of applications in which pumps are used, each with their own advantages and disadvantages.

•One set of seal faces (a rotating face and a stationary face)

•A single elastomer (like an O-ring) for secondary sealing

•Typically spring-loaded

•Simple, cost-effective

•Easy to install and maintain

•Suitable for clean, non-hazardous fluids

•Leaks small amounts of fluid (film evaporation)

•Not ideal for toxic, abrasive, or high-pressure fluids

•Susceptible to dry running

•Water and wastewater treatment

•Irrigation pumps

•HVAC circulation systems

•General industrial utility pumps

•Two sets of seal faces

•A barrier (or buffer) fluid is circulated between the seals

•Pressurized (double) or unpressurized (tandem) depending on configuration

•Back-to-back: rotating faces outward, high-pressure barrier fluid

•Tandem: secondary seal acts as a backup; used with buffer fluid

•Face-to-face: both seals face inward; more complex and less common

•Very low leakage to atmosphere

•Can handle hazardous, abrasive, high-pressure, or high-temperature services

•Extends seal life in tough conditions

•More expensive and complex

•Requires a seal support system (API Plan 53/54, etc.)

•More installation and maintenance effort

•Petroleum and chemical processing (e.g. toxic/flammable fluids)

•Slurry pumps in mining

•Pumps handling polymers, resins, or caustics

•High-pressure boiler feedwater systems

•Preassembled unit with all components aligned and sealed

•Includes gland, sleeve, seal faces, and secondary seals

•Comes in single or double configurations

•Foolproof installation – minimizes human error

•Less downtime, easier to replace

•Ideal for plants with minimal technical staff

•Higher initial cost

•May have size constraints in some older equipment

•Refineries and power plants

•Food and beverage production (sanitary versions available)

•OEM pumps for packaging and processing systems

•Uses a bellows element instead of a spring to maintain contact

•Metal bellows for high-temp/chemical, elastomer bellows for simpler duties

•No dynamic O-ring, so better for sticky, viscous, or crystallizing fluids

•Metal bellows: excellent for high-temperature or corrosive environments

•More expensive

•Metal fatigue can occur over time

•Chemical reactors (high temp/acids)

•Heat transfer fluid pumps (hot oils, glycols)

•Food-grade or aseptic systems (elastomer bellows)

Call us on (02) 4271 2220

email us here or complete the order form below